Glycol Chiller Systems

New Articles & Literature about Glycol:

Ethylene Glycol – The Heat Transfer Fluid of Choice

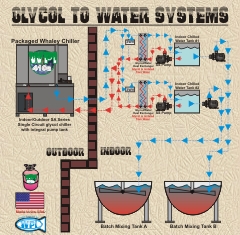

A Typical Glycol to Water Installation

Modular Glycol Closed Loop System

EG & PG Product Guides (2 Pages)

|

|

|

|

|

|

There are many applications for high, medium and low temp glycol chillers. WPI recommends all chillers use a minimum % mix of EG ethylene glycol or (FDA) Food and Drug Administration approved pharmaceutical grade PG propylene glycol depends what the application is. Both %EG and %PG provides freeze protection for the evaporator, pumps and piping as well as rust prevention.

a. Ethylene Glycol (EG) fluid is a colorless practically odorless, low volatile hygroscopic liquid that does not contain any foreign additives. EG is ideal for recirculation chillers and heaters, and has good rust inhibitors. EG can be diluted from 1-100% with water. EG is safe because it has a high flash point of 240F.

b. Propylene Glycol (PG) is an excellent antifreeze and fluid transfer medium. PG’s key advantage is its low toxicity and is biodegradable and does not persist in the environment.

Without a properly designed system and knowing the application, it is possible for the evaporator to freeze-up operating at 50-70F supply temperature. Typical causes of internal evaporator freeze-up : No antifreeze protection during low flow or low charge operations, low flow caused by high line loss or high pressure drop without antifreeze, line restrictions without antifreeze. Flow switch will not open up unless you get almost a complete no flow low flow occurred. with compressor interlock, low Freon or low ambient, and no antifreeze protection in the chiller loop. Although we install flow safety switches and low pressure safety for freeze protection a system is not fail safe without the right mix of (antifreeze fluid protection).

|

Heat Transfer Systems  |

Fail-safe anti-freeze protection: WPI’s Compa-Chill chillers have been field tested in very rough environments since 1993. We install our chillers in low flow applications where the chiller is 100s of feet from the heat load with high line loss. These situations create low flow through the evaporator therefore potentially freezing up the evaporator over time and not getting 100% cooling. The processor should run antifreeze in this situation but we offer a dual pump option with low ambient head pressure fan cycling with crankcase heater and standard low pressure freeze stat protection. Another option we provide is a flow switch which interlocked with the compressor.