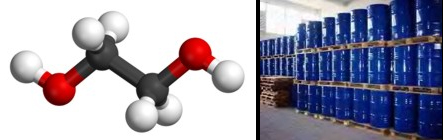

Ethylene Glycol

The Heat Tranfer Fluid of Choice

Product Overview:

Ethylene glycol is an antifreeze product used in industrial glycol cooling equipment. Its primary use is in industrial cooling applications as freeze protection and rust inhibiting. Percentage of glycol used can be determined by a location’s lowest outdoor ambient temperature and also the temperature of the process application loop.

Toxicity:

Toxicity of ethylene glycol plays a major role in an engineer’s decision to use it over propylene glycol. Propylene glycol is used primarily in more food process applications due to its lower risk of contamination. Often, double wall heat exchangers are utilized if a food process cannot risk having their potable water loops contaminated with propylene glycol. If a standard plate & frame is utilized, often a glycol sensing device is used on the potable water side of the heat exchanger in order to detect contamination as soon as it occurs to avoid ruining further food product.

Rust Prevention:

Corrosion due to rusting can occur and lead to major problems for a process cooling loop if the proper precautions are not taken. Therefore, rust inhibiting glycol is used. Typically, rust inhibiting glycol is more expensive than regular pure ethylene glycol, but the benefits highly out-weigh the extra costs. Using rust inhibiting ethylene glycol can allow you to use cast iron or heavy grade PVC piping, which alleviate the costs of installing expensive copper or stainless.

Other Freeze Protection Measures:

There are several other methods WPI uses to secure its equipment from freeze-up in the worst parts of winter. Installing adjustable low pressure cut out switches in refrigerant circuits Installing a dual pump configuration to allow proper flow through the chiller’s evaporator at all times. Installing a flow switch off the discharge of the evaporator circulation pump to cut out the compressor in the event the flow drops out through the evaporator.

Alternatives to Glycol:

There are many alternatives to using glycol. The main alternative WPI uses is a glycol to water configuration. Glycol to water configurations isolate the glycol from processes, yet still allow an outdoor chiller the ability to protect itself during harsh winter months. Other products such as dynalene and other various pre-mixed heat transfer fluid blends can be utilized depending on the application and installation location.

Summary:

Whaley Products, Inc. can assist your company in supplying you with a high quality product at a competitive price. WPI has many years of application engineering experience. We can provide you with as much or as little customization as you would like depending on your project requirements.